Kugwiritsa Ntchito Mwathunthu kwa Zinyalala Kutentha Kuyanika System

Kugwiritsa Ntchito Mwathunthu kwa Zinyalala Kutentha Kuyanika System

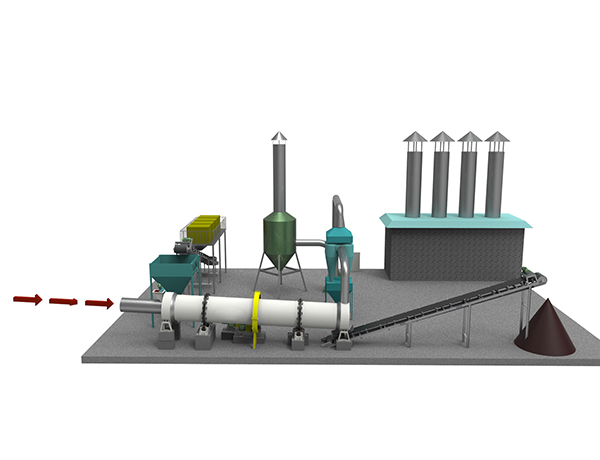

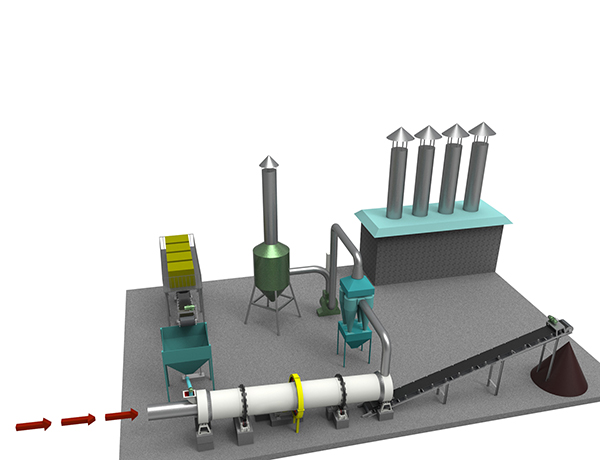

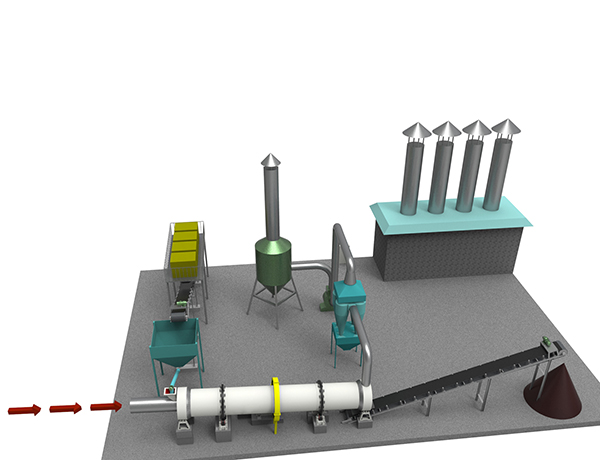

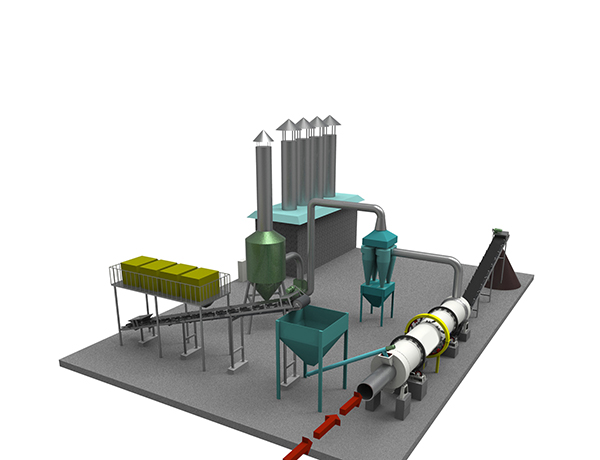

Njira Yoyenda

Chiwembu chokulitsa kugwiritsa ntchito mphamvu yamagetsi yamatenthedwe amatha kupangidwa motengera zinthu zosiyanasiyana, kutentha kwapang'onopang'ono ndikutaya kutentha.

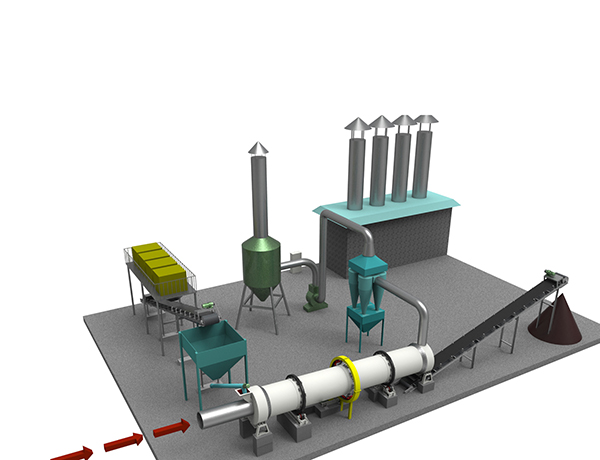

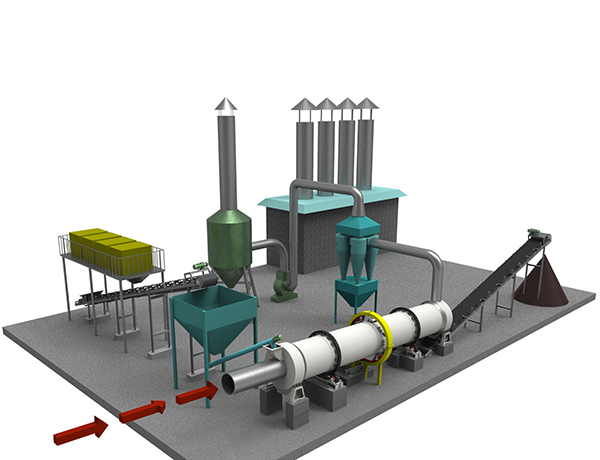

Milandu 1: 200T / D Sludge Processing Project ya imodzi mwa Makampani a Dalian Petrochemical, ndi kutuluka kwa mpweya: 750000 Nm³ / h;kutentha kwa mpweya: 135 ℃;Mapangidwe athu ndikugwiritsa ntchito ma seti atatu a VS 4 x 32m zowumitsira, zomwe zidapangidwa.

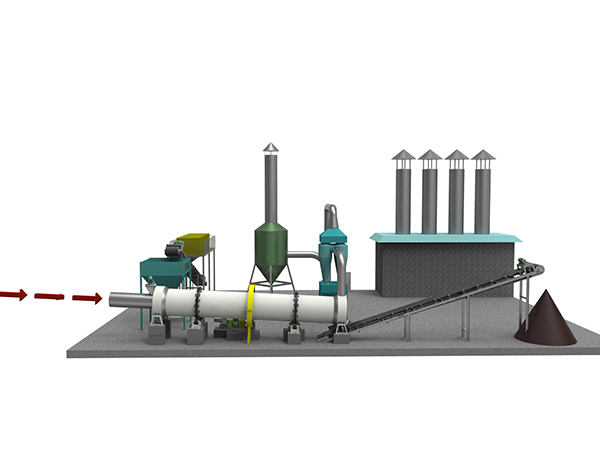

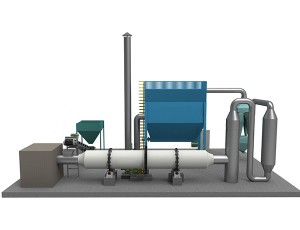

Mlandu 2: 4T/D Sludge Processing Project ya imodzi mwa mafakitale opaka utoto ku Shanghai, utsi otaya: 10000Nm³/h, kutentha kwa mpweya:180 ℃;Mapangidwe athu ndikugwiritsa ntchito VS 2 x 5m intermittent dryer, yomwe yapangidwa.

Ubwino Wadongosolo

1. Kugwiritsa ntchito kutentha kowonongeka, kupulumutsa mphamvu ndi kuteteza chilengedwe;

2. Palibe kugwiritsa ntchito mafuta, kugwiritsa ntchito mphamvu zochepa, njira yoyamba yochotsera fumbi ingagwiritsidwe ntchito kupulumutsa ndalama;

3. Pezani zopangira kwanuko, malo owonjezera safunikira;

4. High mlingo wa zochita zokha, ntchito yopulumutsa;

5. Nthawi yowumitsa imatha kusinthidwa, ndipo madzi amatha kuwongoleredwa atatha kuyanika.

Magawo aukadaulo

| Chitsanzo | Silinda awiri (mm) | Utali wa silinda (mm) | Voliyumu ya silinda (m3) | Liwiro la cylinder rotary (r/min) | Mphamvu (kW) | Kulemera (t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |